Revolutionizing Supply Chain Management with IoT Technology

September 9, 2024

Introduction

Supply chains are complex networks of interconnected systems which make use of digital tools, technology, and procedures. Efficiently handling these complexities can be impeded by a number of issues, ranging from data storage and risk management to inventory control and transportation solutions.

Creative technical and business solutions are more crucial than ever as global supply networks become more integrated. Internet of Things technology is expected to cause a drastic transformation in the supply chain and logistics industry. By connecting sensors, devices, and entire systems, IoT technologies enable real-time data collection, increase communication, and automate numerous steps of supply chain management processes.

This technology, offering unprecedented levels of control and efficiency, is quickly gaining momentum and changing how businesses handle logistics operations, from delivery to procurement and everything in between.

This blog explores the ways in which IoT in supply chain management is transforming operations, offering insightful information to developers building IoT platforms, stakeholders interested in streamlining supply chain processes, and decision-makers seeking to maintain their edge in a changing market with emerging technologies.

IoT: What it is and How it Boosts Supply Chain Management

Internet of Things, usually referred to by the acronym IoT, is a network of sensors and devices that are connected to and communicate with one another in order to gather data and share information. Simple sensors that keep an eye on their environment to intricate systems that oversee entire operating procedures are all examples of IoT tools’ varying degrees of sophistication. The insights supplied by IoT devices enable real-time insights, operation optimization, predictive analytics, and intelligent decision-making.

IoT has a substantial and growing effect on supply chain management. Up from more than US$ 12.4 billion in 2023, the worldwide IoT supply chain industry is projected to grow to an astounding USD 41.8 billion by 2033. IoT technology is predicted to have a CAGR of 12.9% from 2023 to 2033, demonstrating how it is becoming more and more popular for supply chain operations optimization.

IoT provides real-time environmental data on a range of supply chain management characteristics. For instance, IoT sensors may track the whereabouts and conditions of items in transportation, keep an eye on the stock levels in warehouses, and even forecast when equipment and storage facilities will require maintenance. The business benefits of IoT software development can thus improve the entire supply chain.

The data collected automates repetitive procedures, boosts overall productivity, and facilitates better communication between logistics managers and various supply chain components. IoT technologies give logistics and supply chain organizations more resilience, visibility, and control, which has changed the way they operate.

Advantages of Incorporating IoT in Supply Chain Management

Enhanced Inventory Management

By offering real-time insights, IoT technologies improve inventory management efficiency and accuracy.

- Real-Time Tracking: Live tracking of products and assets is made possible by IoT, which offers precise, current insights on inventory levels as well as locations. This feature guarantees that businesses have reliable control over their inventory, which helps to manage stock levels, decrease surplus inventory, and prevent stockouts.

- Reduced Ambiguity: IoT supply chain management operations are less unpredictable, which provides clear and accurate data on stock and asset status. With the help of this information, errors and inconsistencies can be reduced, leading to better decision-making and more efficient stock management.

Increased Visibility

IoT gives businesses better visibility over the whole supply chain process, especially warehouse operations, enabling them to control and track every facet in real time.

- Transparency: IoT makes supply chains more visible, which significantly boosts overall operational efficiency and gives stakeholders the ability to make wiser decisions. IoT lets organizations monitor each link in their supply chain by offering deep insights and real-time data.

- Breaking Silos: IoT enables the integration of diverse components throughout the supply chain, breaking down old silos effectively. This integration promotes better communication and collaboration between divisions, resulting in a more cohesive and effective supply chain operation.

Enhanced Predictive Maintenance

IoT transforms maintenance practices by offering advanced notice of potential equipment issues via continuous monitoring and analysis. This technique allows organizations to address maintenance issues before they become problematic.

- Preventing Breakdowns: IoT plays an important role in predictive maintenance because it uses sensors and data analytics to forecast equipment faults before they occur. This proactive method enables prompt maintenance interventions, considerably reducing the chance of unanticipated problems and minimizing operational delays.

- Cost Savings: Employing IoT-driven predictive maintenance saves money by avoiding the high costs of unexpected downtime and emergency repairs. Businesses can maximize equipment longevity, save repair costs, and enhance overall performance by addressing issues with maintenance proactively.

Improved Efficiency

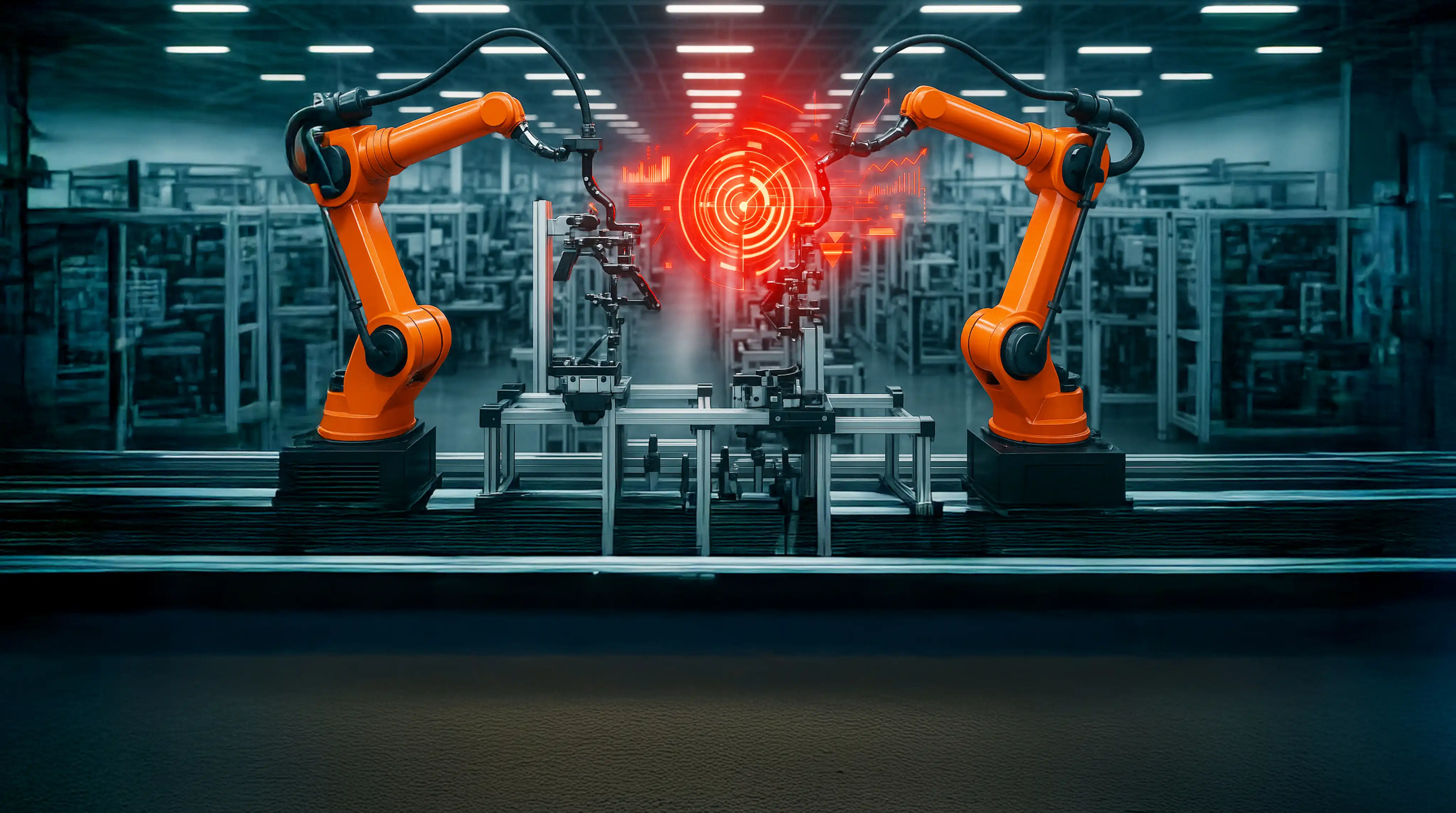

An IoT-based solution improves productivity by automating common tasks and business processes, leading to smoother business operations with reduced reliance on human involvement. Organizations can improve productivity by leveraging relevant data and automated technologies.

- Automation: Routine actions and procedures in supply chain management are automated by IoT devices, doing away with the need for human input and involvement. Since automation speeds up procedures, decreases human error, and frees up developers for more strategic tasks, it increases operational efficiency.

- Resource Optimization: IoT improves resource management by offering in-depth knowledge of operational requirements and usage trends. This data-driven strategy contributes to waste reduction, resource allocation optimization, and cost savings, resulting in a more economical and sustainable supply chain.

Better Risk Management

IoT has become extremely useful for supply chain management and logistics risk management and mitigation since it improves security protocols and allows for comprehensive analysis and early identification of possible problems.

- Early Detection: IoT sensors continuously keep an eye on storage conditions across a variety of supply chain components, offering early alerts for any issues like equipment failures or changes in environmental conditions. Because of this early detection, companies can handle risks more proactively, preventing operational disruptions and addressing issues before they become more serious.

- Enhanced Security: Real-time IoT enhances supply chain security and reduces fraud by providing live notifications and monitoring. IoT devices can detect suspicious activity and possible security concerns by monitoring assets and activities throughout the supply chain. This enables prompt response to security threats and safeguards against fraud and theft.

Improved Customer Experience

By improving visibility and guaranteeing high-quality products through sophisticated monitoring and communication, IoT in supply chain improves the entire customer experience.

- Real-Time Updates: Supply chain and logistics companies can now offer customers real-time order updates thanks to IoT, increasing customer satisfaction and transparency. Customers receive fast access to tracking details and status updates, which makes them feel more informed and improves their overall delivery experience.

- Quality Assurance: IoT keeps an eye on conditions at every step of the supply chain, which helps to preserve product quality. In IoT-driven warehouse automation, sensors monitor handling procedures and environmental conditions, enabling companies to see possible quality problems early. Thanks to this proactive approach, customers are guaranteed to obtain items that fulfill high-quality requirements.

The Challenges of Implementing IoT in Supply Chains

Integrating with Existing Systems

There may be significant challenges when introducing IoT applications to the supply chain infrastructure. For the integration and operations to be successful, these need to be resolved.

Making sure that emerging IoT technologies are compatible with existing infrastructure and legacy systems is one of the biggest challenges. Potential obstacles could arise from the use of antiquated protocols or technologies in existing systems, which make them difficult to integrate with contemporary IoT platforms.

Firms should consider implementing IoT solutions that support many communication protocols and have flexible integration options in order to get past compatibility difficulties. Using IoT platforms or middleware can be helpful in bridging the gap between outdated and contemporary systems. Investing in system upgrades and phased installations can also help to streamline integration and minimize interruptions to daily operations.

Data Security Threats

Owing to the private nature of the details, it is critical to preserve privacy and secure data while using IoT in supply chains.

A wide range of connected sensors and devices that gather and exchange vast amounts of data usually make up IoT systems. Due to their interdependence, they could be at risk of data breaches. Unauthorized access to confidential information, data manipulation, and the disclosure of private or vital company information are a few potential security threats.

Companies should put strong authentication procedures in place, encrypt data while it’s in transit and at rest, and update security patches often to guarantee privacy and security. Another way to prevent unwanted access to valuable data, is to use secure communication channels and network segmentation. To further improve data protection and privacy in IoT-enabled supply chains, frequent security assessments and employee training on best practices are recommended.

Scalability and Costs

A logistics company must carefully assess the difficulties and financial ramifications before attempting to implement IoT throughout extensive supply chains.

The diversity and complexity of all the systems involved make deploying IoT technologies across a vast supply chain difficult. Ensuring consistent performance, managing growing data volumes, and preserving interoperability across regions or facilities are all significant obstacles. Furthermore, as the scale of operations expands, so too do the demands on network infrastructure and information processing capabilities, putting existing resources – including budgets – under strain.

Implementing IoT can involve significant initial expenses to set up hardware and software and conduct personnel training. However, these upfront costs should be balanced against the long-term benefits of IoT, which include lower operational costs, higher efficiency, and better decision-making. Companies can successfully manage expenses while realizing the full value of their IoT investments by implementing in stages and prioritizing high-impact areas.

Future Trends for IoT in Supply Chain Management

5G

The introduction of 5G technology is expected to transform IoT in supply chains by greatly improving connection and information processing capabilities. 5G will enable real-time communication between IoT devices, boosting responsiveness and precision by reducing latency and increasing transmission speed. This will result in more dynamic and adaptable supply chains that can respond to changes in demand and supply swiftly.

AI/ML

The integration of artificial intelligence algorithms and machine learning models with IoT technology holds promise for creating intelligent and effective supply chain management solutions. The large amounts of data and information produced by IoT devices can be utilized by artificial intelligence and machine learning models to predict trends and optimize processes, which can then lead to computerized decision-making and more precise demand forecasting, all of which can decrease waste, cut costs, and improve overall supply chain efficiency.

Blockchain technology

Blockchain technology and IoT provide exciting new possibilities for supply chain management in security and traceability. Blockchain provides a decentralized, tamper-proof database for transactions, and it can ensure that every product movement is safely recorded and tracked. This can assist with preventing fraud and counterfeiting while also ensuring that items adhere to quality and regulatory standards.

Conclusion

The integration of IoT in supply chain management is more than just a technology trend; it is a transformative strategy that may provide organizations with a substantial competitive advantage. IoT has the power to revolutionize logistics and supply chain operations by improving visibility, efficiency, and decision-making.

Our expert software developers can provide tailored IoT solutions to match your specific requirements. Contact us today at [email protected] to set up a consultation and learn more about how we can help you transition to a more efficient and innovative supply chain and logistics management system.